Batteries That Work.

The way our customers need them to.Shift’s flexible design provides a solution for every type of ship, and every type of customer. Keeping you safe in the harshest environments in the world – everyday.

Safety

Testing

A nail penetration test is the worst thing you can do to a lithium battery cell. It causes the entire cell to fail spontaneously and instantly. The cell in the module is failing as dramatically as the unmanaged cell but is instead being controlled by Shift safety mechanisms. The adjacent cells in the module did not reach high internal temperatures and remained undamaged. All gasses are safely released through the ventilation system in the back of the module.

Testing

A nail penetration test is the worst thing you can do to a lithium battery cell. It causes the entire cell to fail spontaneously and instantly. The cell in the module is failing as dramatically as the unmanaged cell but is instead being controlled by Shift safety mechanisms. The adjacent cells in the module did not reach high internal temperatures and remained undamaged. All gasses are safely released through the ventilation system in the back of the module.

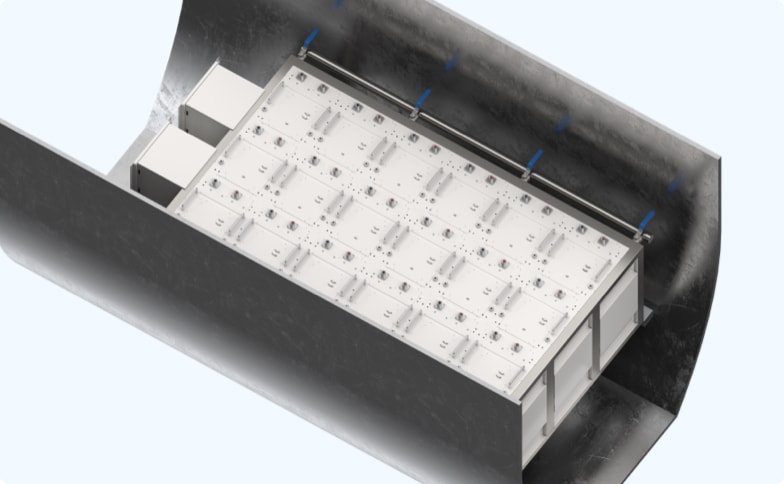

Installation Options

Practical Electrification

Manufactured for consistency. Customized for each customer.

Cellswäp

Reducing our net carbon impact

Reducing our net carbon impact. Instead of replacing the system every 10 years, we re-use primary components and replace and recycle only the cells.

Retrofit Process

Rebuild the inside of a battery onboard

to save money.

Recycling

Replace only the cells at the end of the system life instead of the whole system.

Quality & Performance

Lower battery cost, reduced size and performance guaranteed for life.

ESS must be replaced in their entirety. 1MWh system = 1800kg of metal waste

Software

Safety Software that Never Sleeps

All-in-one platform analyzes and supervises key battery performance indicators and performance 24/7 for your entire fleet. OnWatch enables proactive maintenance, enhanced battery life and conserves reliability of every single module.

Specifications

Single Module BBU

Specifications

Single Module BBU

- Power 66 – 15000 cycles

- Power 75 – 15000 cycles

- Energy 91 – 13000 cycles

- Power 66 – 3C

- Power 75 – 3C

- Energy 91 – 1C

- L 580mm / H 380mm / W 320mm

- 93kg

- Power 66 – 6.6kWh

- Power 75 – 7.5kWh

- Energy 91 – 9.1kWh

- 77-100VDC

- Power 66 – 225A

- Power 75 – 225A

- Energy 91 – 100A

- IP67

- Contactor

- Yes